Email:

Re-sharpening Services

Our Re-sharpening Services include regrinding of all types of industrial carbide and HSS tooling, such as end mills, drills, step tools, reamers, mill cutters, and more.

Our CNC grinding capabilities mean we are able to hold extremely high tolerances and fine finishes with as good as new or better than new results. With our ANCA 5 axis cutter grinding software, we grind a vast variety of Hi-Performance drill points.

Our CNC grinding capabilities mean we are able to hold extremely high tolerances and fine finishes with as good as new or better than new results. With our ANCA 5 axis cutter grinding software, we grind a vast variety of Hi-Performance drill points.

We service customers and manufactures in a wide variety of industries including:

- Automotive

- Defense

- Machining

- Manufacturing

- Moldmaking

- Tool and Die

Our team custom manufactures and sharpens tools made for your unique specifications.

Drills

We sharpen and/or modify Hi-Performance Carbide, Carbide, Hi-Speed Steel, center drills, spot drills, auger bits, step drills (single and multiple steps), tapered drills, core drills and left hand drills. Drills can be modified to your specifications.

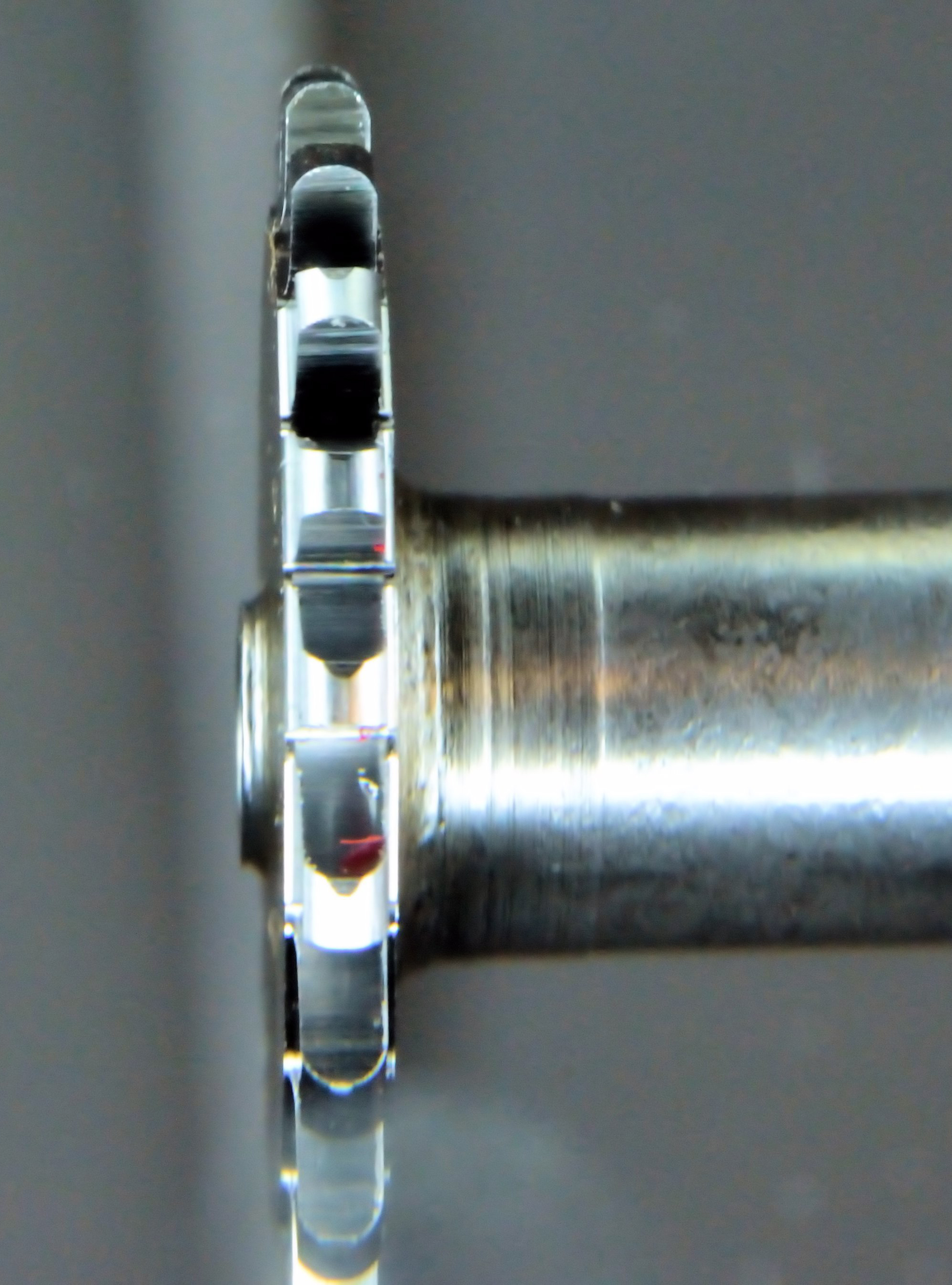

Reamers

Reamers

We modify, and sharpen Carbide, Carbide Insert, and HSS straight flute reamers, spiral flute, tapered and step reamers (single step and multiple steps).

Misc

We modify, and sharpen spiral and straight flute taps, scribes and engraving tools, counterbores, corner rounders, concave/convex cutters, radius cutters, T-slot cutters, milling cutters, punches, dies and roto broaches.

Countersinks

We re-sharpen HSS and Carbide, chatterless countersinks, multi-flute and single hole countersinks.

End Mills

We sharpen, and modify Cobalt, HSS, and Carbide end mills, angled, tapered, ball end mills, chamfer mills, shell mills, dovetails.

Looking for New Tool Pricing?

See PTG’s current price list for tools such as Hi-Performance carbide end mills, and standard Carbide end mills. For special tools, call us or send a print.